See Barrier free and Extruded Base designs

Choice of color enhances the appeal of these handsome safety stair nosings. Designed for heavy duty use indoors and outdoors, these safety nosings meet and exceed all OSHA and Barrier-Free requirements.

IMPACT RESISTANT: These nosings are manufactured from an extruded aluminum base filled with a mixture of anti-slip abrasive granules in an advanced formula epoxy binder. Their remarkable strength is capable of absorbing heavy impact.

BARRIER-FREE: The designs shown are in compliance with the Barrier-Free Code, ensuring those physically impaired complete access to public buildings.

ANTI-SLIP SURFACE: Each abrasive-filled rib projects above the aluminum base for the greatest exposure of anti-slip surface in any tread now being produced in the United States.

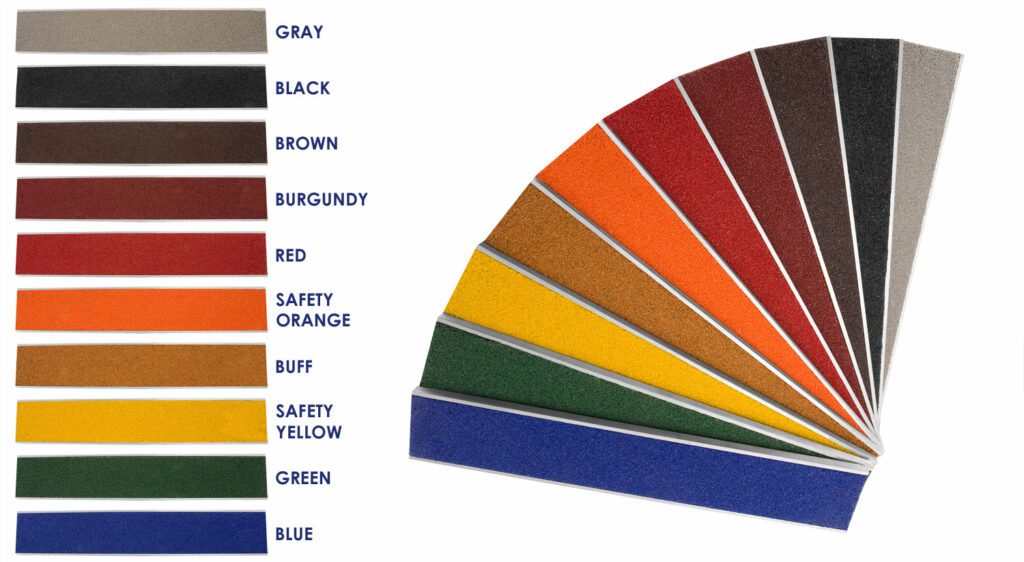

CHOICE OF COLOR: Colors are locked into the epoxy abrasive mixture and will not fade or wear off, maintaining a rich color to blend with any decor.

ECONOMICAL: Using our exclusive automated filling machinery, these extruded base safety nosings are manufactured et three times the speed of ordinary methods. This labor saving method reduces cost.

How to Specify

Stair nosings shall be type No._________ as manufactured by American Safety Tread Company, Helena, Alabama 35080.Telephone 1-800-245-4881. The base shall consist of heat treated extruded aluminum alloy 6063-T6. The abrasive filler shall consist of a mixture of aluminum oxide and silicon carbide granules in an epoxy matrix locked into the extruded channels of the base. The abrasive ribs shall project a minimum of 1/16 inch above the extruded channels. Nosings shall terminate not more than 3″ from ends of steps for poured concrete stairs;for concrete filled steel pan stairs, nosings shall be full length of steps less 1/8″ clearance.

Color shall be as selected by the architect.